The HudcoAir® Air Conveyor System

Hudco Industrial Products, Inc. is delighted to offer the revolutionary HudcoAir® Conveyor. The most efficient belt conveyor in the world is also the cleanest and requires the least maintenance. The HudcoAir® Conveyor uses low-pressure air to support the loaded belt in place of traditional troughing rollers. This revolutionary concept minimizes friction, lowers power consumption, requires minimum maintenance, and is remarkably quiet and environmentally friendly. The HudcoAir® Conveyor consists of a specially built plenum pressurized by a low horsepower blower. The top surface of the plenum is designed with a precisely perforated trough to “cradle” the belt. As the pressurized air is released from the holes in the trough it creates a film that actually levitates the belt from frictional contact with the trough. In other words, the belt literally floats on air!

There is no limit to the bulk products that can be transported on a HudcoAir® Conveyor. Coal, sand, limestone, woodchips, fly ash, phosphate, cement and even iron ore can easily be transported. Movement of the belt is extremely smooth, quiet, safe and dust free while using less total horsepower than a conventional roller supported conveyor.

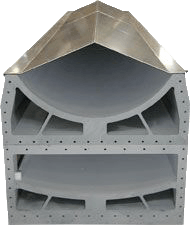

HudcoAir® Plenum with Air Return